Machinable tungsten alloy: Tungsten alloy weight block

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 5PCS |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-CM-053

Brand: ZZJD

Place Of Origin: China

Size: Custom-made

Material: 85-99% Tungsten

Denstiy: 15.8-18.75 g/cm3

Surface: Sintered, Forged, Grounded

PACKAGING & DELIVERY

Selling Units : Kilogram

Package Type : Standard export packing

DESCRIPTION

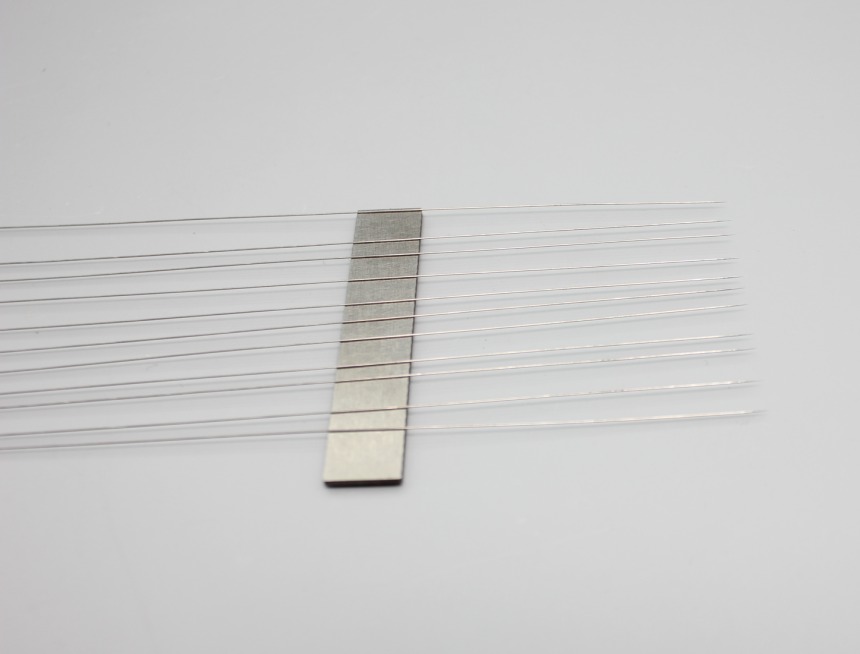

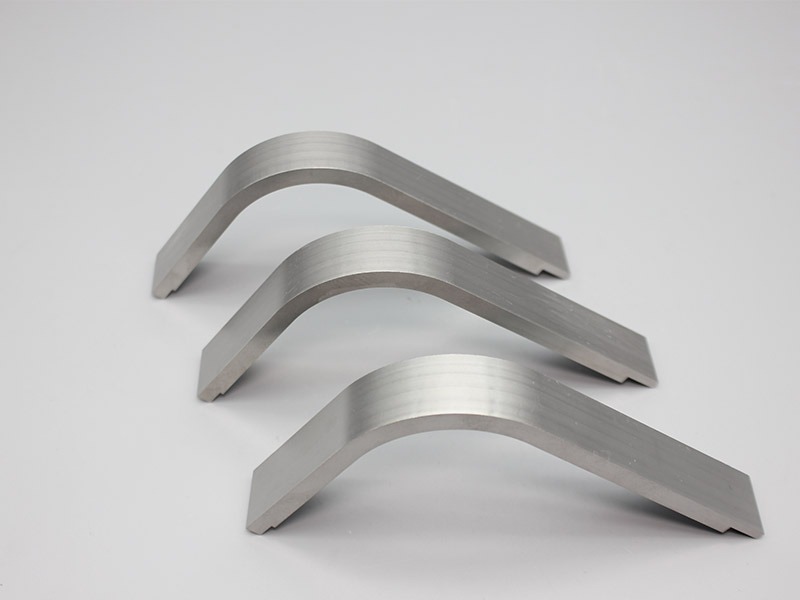

Tungsten Alloy Weight Block – High-Density Precision Ballast for Critical Applications

Tungsten alloy weight blocks are engineered components made from tungsten-heavy alloys (WNiFe, WNiCu) with densities ranging from 17.0 to 18.5 g/cm³. These blocks provide maximum mass in minimal volume, making them ideal for counterbalancing, vibration damping, and radiation shielding in aerospace, industrial, and medical fields.

Key Features & Benefits

Ultra-High Density – 50% denser than lead, 2.3X denser than steel.

Precision Machining – CNC-ground to tight tolerances (±0.01mm).

Corrosion Resistance – Withstands harsh environments (saltwater, chemicals).

Non-Toxic & ROHS Compliant – Eco-friendly alternative to lead or depleted uranium.

Customizable – Tailored sizes, shapes, and mounting features (holes, threads).

Technical Specifications

Parameter Standard Range Custom Options

Material WNiFe (90-97% W) WCu, WMo, WNiCr

Density 17.0–18.5 g/cm³ Up to 19.3 g/cm³ (sintered)

Dimensions 10mm – 300mm (L/W/H) Larger sizes via HIP

Tolerance ±0.05mm (as-sintered) ±0.01mm (ground)

Surface Finish As-sintered, ground Polished, Ni-plated

Mounting Threaded holes, grooves Custom CNC machining

Primary Applications

Counterweights & Balancing

Aerospace: Aircraft control surfaces, satellite rotors, drone stabilizers.

Automotive: Luxury vehicle vibration damping, racing components.

Industrial: CNC machinery, robotic arms, high-speed rotors.

Radiation Shielding

Medical: PET/CT collimators, isotope containers, syringe shields.

Nuclear: Reactor shielding, fuel rod handling tools.

Research: Neutron absorbers, particle accelerator components.

Tooling & Manufacturing

EDM Electrodes: (WCu) for precision machining.

Boring Bars: Vibration damping in deep-hole drilling.

Molds & Dies: High-pressure casting/extrusion.

Performance Comparison

Material Density (g/cm³) Corrosion Resistance Machinability

Tungsten Alloy 17.0–18.5

Lead 11.3

Steel 7.8

Depleted Uranium 18.6

Customization Options

Alloy Tailoring: Adjust W/Ni/Fe ratios for optimal density/ductility.

Precision Machining: Holes, threads, grooves, and complex geometries.

Coatings: Ni-plating (corrosion resistance), DLC (wear resistance).

Certification: ISO 9001, ITAR, ASTM B777 compliance.

Why Choose Our Tungsten Weight Blocks?

High-Quality Sintering: Uniform density with >99.5% theoretical density and no voids.

Full Metrology: 3D CMM inspection ensures precise dimensions.

Rapid Prototyping: 2-week lead time for custom samples.

Global Logistics: DDP shipping to aerospace/defense hubs.

FAQs

Q: What is the maximum size available?

A: Blocks up to 500mm x 500mm x L via hot isostatic pressing (HIP).

Q: Can tungsten blocks be used in MRI environments?

A: Yes! WNiFe alloys are non-magnetic and MRI-safe.

Q: Are they RoHS compliant?

A: Absolutely! Our alloys are 100% lead-free and eco-friendly.

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU