Tungsten alloy heavy-duty screw

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 5pcs |

| Transportation: | Ocean,Air,Express |

Attributes

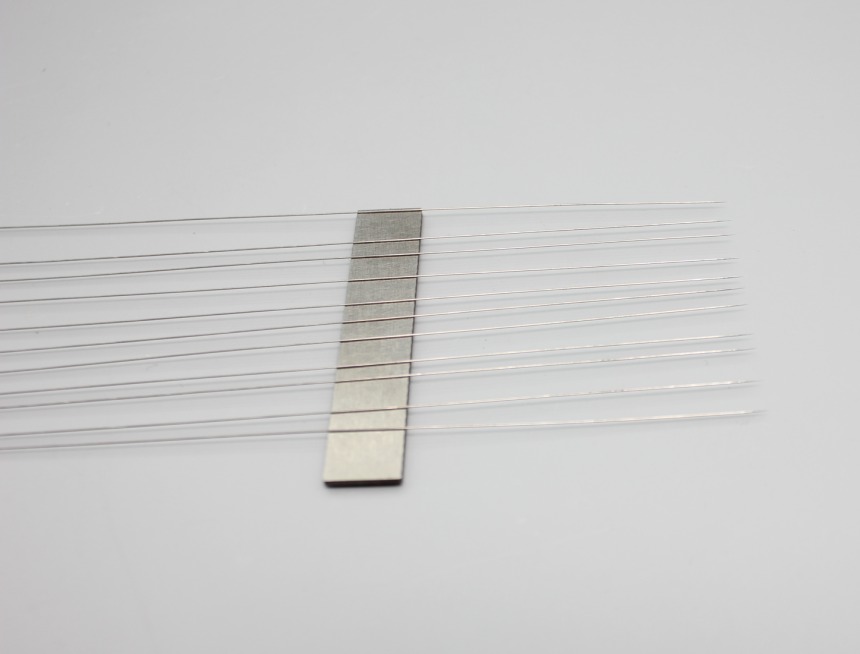

Model No.: JDTG-CM-094

Brand: ZZJD

Place Of Origin: China

Size: Custom-made

Material: 95% Tungsten

Denstiy: 18.1g/cm3

Surface: Polished

PACKAGING & DELIVERY

Selling Units : PCS

Package Type : Standard export packing

DESCRIPTION

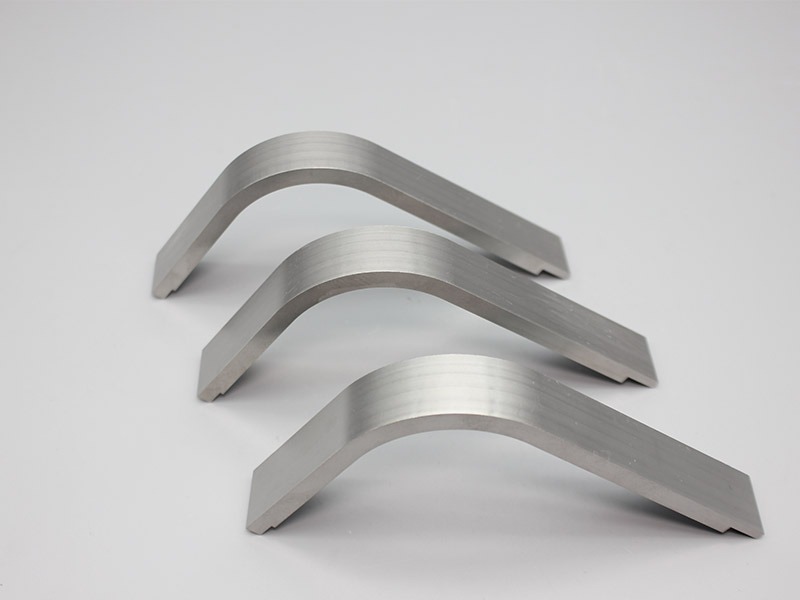

Tungsten alloy heavy-duty screw is a type of high-strength fastener primarily made of tungsten alloy, designed to withstand heavy loads and harsh environments. Following is a detailed introduction:

Composition and Manufacturing Process of tungsten heavy alloys

- Composition: Tungsten alloy heavy-duty screws are mainly composed of tungsten, with a content of 85% - 99%. They are often alloyed with elements such as nickel, iron, copper, or tantalum. These additives can improve the mechanical properties, such as toughness and ductility, of the screws, while maintaining the high-density and high-melting-point characteristics of tungsten.

- Manufacturing Process: Usually, the powder metallurgy process is adopted. First, high-purity tungsten powder and alloying element powders are mixed in a certain proportion. Then, they are formed into blanks through pressing and sintered at high temperatures to obtain screws with the required shape and performance. Finally, surface treatment such as plating or coating may be carried out to enhance corrosion resistance and wear resistance.

Performance Characteristics of tungsten alloys

- High Density: The density of tungsten alloy heavy-duty screws is generally 16.5 - 18.5 g/cm³, much higher than that of ordinary steel screws. This high density gives them excellent counterweight performance and can effectively resist vibration and impact.

- High Temperature Resistance: Tungsten has a very high melting point of 3422 °C. Tungsten alloy screws can still maintain 70% - 80% of their room-temperature strength at high temperatures, which enables them to work stably in high-temperature environments such as aerospace engines and industrial high-temperature furnaces.

- High Strength and Wear Resistance: Tungsten alloy heavy-duty screws have high hardness and excellent wear resistance, which can maintain good surface integrity and thread accuracy under high-load and high-friction conditions, with a long service life.

- Good Corrosion Resistance: Tungsten alloy has good chemical stability. In the 常温 environment, it hardly reacts with water, oxygen, and most acid and alkali media. After surface treatment, its corrosion resistance can be further enhanced.

- Radiation Shielding Performance: Due to their high density, tungsten alloy heavy-duty screws can effectively absorb γ-rays and neutron radiation, so they are widely used in the nuclear industry and other fields that require radiation protection.

-

Applications of Tungsten alloy heavy-duty screw

- Aerospace Field: In aircraft engines, tungsten alloy heavy-duty screws are used to fix components such as turbines and combustion chambers, which can resist high temperatures and huge mechanical stresses and ensure the reliable operation of the engine. In spacecraft, they are used in the docking mechanism and satellite attitude control system to meet the requirements of low vapor pressure and low magnetic permeability.

- Nuclear Industry: Tungsten alloy heavy-duty screws are used for the connection of nuclear reactor pressure vessels and the fixing of radiation shielding components, which can not only withstand high temperatures and high pressures but also effectively block radiation.

- Military Field: They are used for the key connections of armored vehicles and weapon systems. For example, in the modular connection of composite armor, tungsten alloy screws can absorb the kinetic energy of projectiles and improve the protection performance.

- Chemical Industry: In chemical reaction vessels, high-temperature furnaces, and chemical pipelines, tungsten alloy heavy-duty screws can resist the erosion of strong corrosive media such as concentrated nitric acid, sulfuric acid, and hydrochloric acid, and can also adapt to high-temperature reaction environments, with a service life ten times longer than that of stainless steel screws.

Customer Questions & Answers

Did not match any questions!

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU