tungsten alloy machining

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW,FCA,Express Delivery |

| Min. Order: |

2 Piece/Pieces |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-CM-056

Brand: ZZJD

Place Of Origin: China

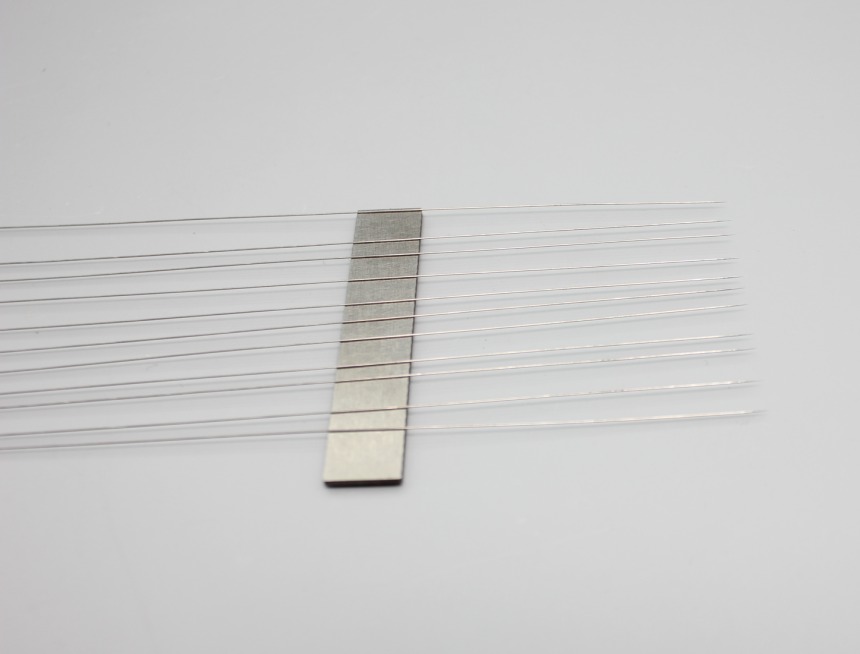

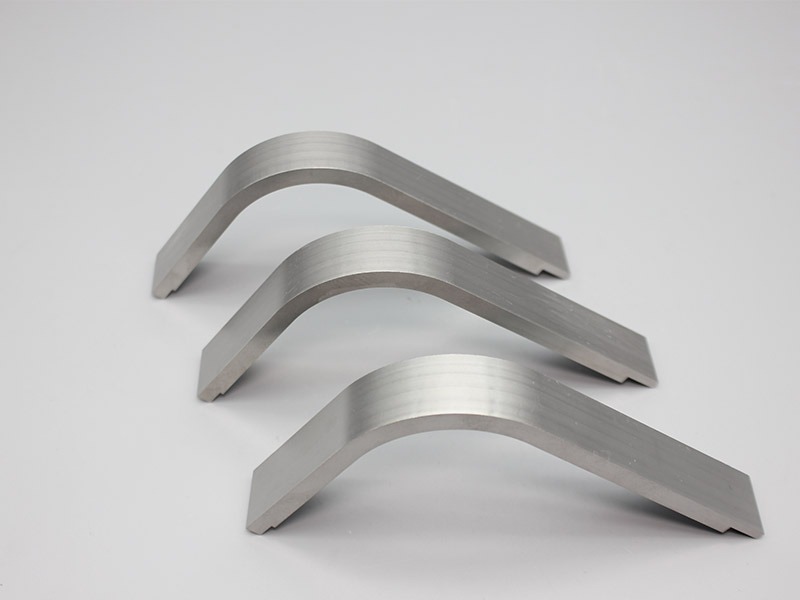

Material: Tungsten

Density: 18.10±0.15g/cm³

Color: Natural

Size: Support customization

PACKAGING & DELIVERY

Selling Units :Piece/Pieces

Package Type : Standard export packing

DESCRIPTION

Tungsten Alloy Mechanical & Electrical Components – High-Performance Solutions

Tungsten heavy alloys (WNiFe, WNiCu, WMo, WC-Co) are widely used in precision mechanical and electrical applications due to their exceptional density, strength, and thermal/electrical properties. Below is a detailed breakdown of their uses, benefits, and manufacturing considerations.

Key Properties for Mechanical & Electrical Applications

Property Advantage Typical Alloys

High Density (17–19 g/cm³) Ideal for counterweights, vibration damping WNiFe, WNiCu

High Hardness (HRA 80–92) Wear-resistant bearings, nozzles, cutting tools WC-Co

Excellent Thermal Conductivity (~110 W/mK) Heat sinks, electrical contacts WCu

Low Thermal Expansion (~4.5 µm/m°C) Stable in high-precision instruments WNiFe

Non-Magnetic MRI-compatible, semiconductor equipment WNiFe

High Melting Point (~3,400°C) Rocket nozzles, plasma electrodes WMo, WCu

Mechanical Applications

1. Counterweights & Balancing Components

Aerospace: Rotor blades, flight control surfaces

Automotive: Crankshafts, flywheels, luxury car damping

Industrial: CNC machinery, robotic arms

2. Wear-Resistant Parts

Bearings & Bushings (WC-Co) – High-load, low-lubrication environments

Valve Balls & Seats – Corrosion-resistant for oil/gas industry

Nozzles & Erosion Shields – Sandblasting, thermal spray coatings

3. High-Strength Fasteners

Tungsten alloy screws, bolts – Used in extreme environments (nuclear, deep-sea)

Electrical & Electronic Applications

1. Electrical Contacts & Electrodes

High-voltage switches (WCu) – Arc-resistant, high conductivity

Resistance welding electrodes – Long lifespan vs. copper

Semiconductor wafer chucks – Non-magnetic, thermal stability

2. Heat Sinks & Thermal Management

WCu (70/30 or 80/20) – Used in laser diodes, power electronics

Microchannel coolers – Efficient heat dissipation in high-power RF devices

3. Radiation Shielding (Electrical Enclosures)

X-ray tubes, CT scanners – Tungsten housings block stray radiation

Nuclear instrumentation – Neutron-absorbing components

Manufacturing Methods

Process Best For Tolerances

Powder Metallurgy (PM) Near-net-shape parts (gears, weights) ±0.1mm

CNC Machining Precision components (electrodes, fasteners) ±0.01mm

EDM (Wire/Sinker) Complex geometries (micro-nozzles) ±0.005mm

Grinding/Polishing Mirror finishes (optical components) Ra <0.1µm

Tungsten Alloy Selection Guide

Application Recommended Alloy Key Reason

Counterweights WNiFe (93% W) High density, machinable

Electrical Contacts WCu (70/30) High conductivity, arc resistance

Cutting Tools WC-6%Co Extreme hardness

Radiation Shielding WNiCr Neutron absorption

#TungstenComponents #PrecisionEngineering #ElectricalContacts #HeavyAlloys

#TungstenMachining #PrecisionEngineering

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU